Introduction

In the area of semiconductor packaging and microelectronic meeting, two dominant cord bonding recommendations stand out: wedge bonding and ball bonding. Both processes are very important in making sure riskless interconnections among chips and substrates, however they arrive with diverse options, blessings, and applications. This article delves deep into the intricacies of those two cord bonding innovations, presenting a accomplished prognosis to recognize which formula reigns excellent in a number situations. Whether you’re a seasoned engineer or simply beginning your trip in twine bonding expertise, this marketing consultant will equip you with invaluable insights.

What is Wire Bonding?

Wire bonding is a strategy used to create electric connections between semiconductor contraptions and their packages. It entails using skinny wires—usually constituted of gold, aluminum, copper, or silver—that are thermally or ultrasonically bonded to pads on a chip and substrate. The twine bonding strategy is the most important for excessive-efficiency electronics as it straight away impacts reliability, performance, and average instrument satisfactory.

The Wire Bonding Process Explained

The wire bonding approach might be damaged down into countless key steps:

Preparation: The surfaces of the chip and substrate are cleaned to remove any contaminants that might have effects on bond first-class. Wire Selection: Depending at the program, engineers decide fantastic supplies (gold, aluminum, copper) structured on motives like conductivity and can charge. Bond Formation: The chosen approach (wedge or ball bonding) is implemented with the aid of really good twine bonding tools. Inspection: Post-bonding inspection ensures that the connections meet exceptional concepts through varied testing strategies.By expertise how wire bonding works, possible realize its integral position in smooth electronics production.

Types of Wire Bonding Techniques

Wire bonding encompasses loads of techniques adapted for extraordinary functions:

- Ball Bonding: Involves forming a ball on the stop of the cord prior to making a bond. Wedge Bonding: Utilizes a wedge-fashioned tool to create bonds devoid of forming a ball on the end. Ribbon Bonding: Uses wider ribbons rather than regular wires for greater floor regions.

Each class has its entertaining set of qualities that have an affect on overall performance in one-of-a-kind eventualities.

Wedge vs Ball Bonding: A Comparative Overview

When evaluating wedge vs ball bonding innovations, it is simple to analyze their center variations:

1. Bond Formation Mechanism

- Ball Bonding:

- Begins with heating the cord's finish to model a small ball. The ball is then pressed towards the bond pad the usage of ultrasonic electricity to create a effective attachment.

- Uses a wedge instrument that presses down at the wire with out forming a pre-bonded sphere. Bonds are created thru mechanical rigidity combined with heat (thermosonic) or ultrasonic vigor.

2. Material Compatibility

Each method favors unique substances:

- Ball bonding predominantly makes use of gold due to the its most well known conductivity. Wedge bonding can make the most of aluminum or copper wires safely.

three. Applications and Industry Use Cases

Both tactics locate their niche across alternative sectors:

- Ball Bonding:

- Widely utilized in microelectronics like IC packaging thanks to its compatibility with great pitch applications.

- Preferred in energy modules and automobile electronics the place increased pads are regular.

four. Cost Consideration

Cost performs an very good role in deciding on among those tools:

| Feature | Ball Bonding | Wedge Bonding | |------------------|--------------------------|---------------------------| | Material Cost | Higher (Gold) | Lower (Aluminum/Copper) | | Equipment Cost | Typically greater | Generally curb |

five. Reliability Factors

Reliability is paramount in electronic packages:

- Ball bonds generally tend to display more suitable fatigue resistance lower than thermal cycling prerequisites. Wedge bonds grant first-rate moisture resistance as a result of their lower tension stages on pads.

Detailed Analysis of Wedge Bonding Process

What Makes Wedge Bonding Unique?

Wedge bonding sticks out wire bonding process owing to its fundamental yet positive mechanism for developing sturdy connections among chips and substrates without having a pre-bonded sphere:

Key Advantages

Material Versatility: Can use a range of cord styles resembling aluminum or copper. Lower Stress: Reduces mechanical stress on pads when compared to different tricks. Ability for Deep Access: Ideal for stacking dies or running inside of confined spaces because of the its layout flexibility.Applications

Wedge bonding reveals software throughout dissimilar industries inclusive of:

- Automotive electronics Power modules Aerospace components

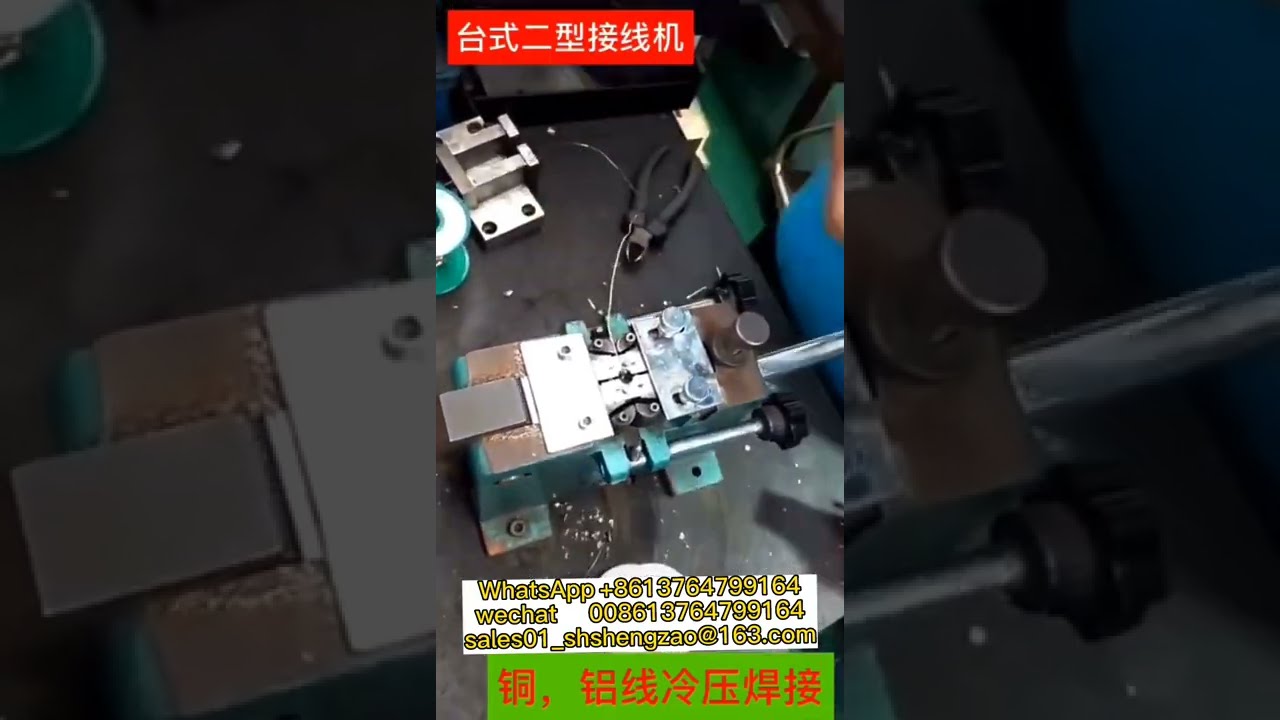

Understanding Wedge Wire Bonding Machines

The fulfillment of wedge bonding closely depends on difficult package designed principally for this cause:

Ultrasonic Wedge Bonders: Utilize ultrasonic vigour for bond formation; excellent for light-weight programs. Thermosonic Wedge Bonders: Combine heat with ultrasonic vigour; worthy while coping with extra hard resources like copper.In-intensity Look at Ball Bonding Process

What Defines Ball Bonding?

Ball bonding is by and large desired in prime-density applications where area is restricted but efficiency demands stay top:

Key Features

Fine Pitch Capability: Allows connections at micro-point pitches bettering ordinary circuit density. Gold Wire Usage: Offers sophisticated conductivity however comes at an improved subject matter charge. Established Technology: Has been around longer than wedge bonding making it generally understood by way of practitioners.Applications

Ball bonding excels awfully in sectors resembling:

- Microelectronics Telecommunications High-frequency RF applications

Exploring Ball Wire Bonding Machines

To achieve most excellent functionality at some stage in ball bonding strategies, specialised equipment is applied:

Thermosonic Ball Bonders: Integrate warmth throughout bond formation which improves adhesion homes greatly. Automatic Ball Bonder Machines: Facilitate mass creation while guaranteeing precision in each and every bond created.Evaluating Wire Bond Quality Control Measures

Quality regulate in the time of equally methods cannot be overstated because it straight impacts yield quotes and product reliability:

1. Inspection Methods

Various inspection concepts make sure that that bonds meet stringent trade criteria:

| Inspection Method | Description | |-------------------------|--------------------------------------------------| | Visual Inspection | Manual assessments via operators by using magnification | | Pull Test | Evaluates the energy of individual bonds | | Shear Test | Assesses adhesive force between layers |

2. Common Failure Modes

Understanding viable failure modes enables mitigate disadvantages linked to either applied sciences:

For Ball Bonds:

- Incomplete Bonds Oxidation Issues

For Wedge Bonds:

- Heel Cracking Pad Damage

Implement rigorous inspections put up-process to seize worries early before they have an effect on downstream manufacturing ranges.

Advantages and Disadvantages of Each Technique

When figuring out between wedge vs ball bonding, think those pros and cons which may impression your production line selections severely:

Advantages of Ball Bonding

Fine pitch power allows compact designs basic for advanced technological know-how integration. Established technique approach large strengthen resources are achieveable along with tutorials and films on line.Disadvantages of Ball Bonding

Higher expenditures related to gold resources may additionally deter price range-acutely aware projects. More not easy equipment required in contrast to some selections consisting of wedge structures.Advantages of Wedge Bonding

Lower operational rates owing mostly to less expensive raw fabrics like aluminum or copper wires used characteristically throughout industries. Enhanced environmental resilience routinely interprets into higher reliability over time exceedingly under extreme conditions fashioned inside of car packages.Disadvantages of Wedge Bonding

Limited applicability relating to exceptional pitch specifications the place tightly packed circuitry exists nerve-racking change ideas like ball bonds as a replacement may perhaps yield enhanced consequences universal from each effectivity & effectiveness perspectives alike.FAQs About Wedge vs Ball Bonding Techniques

Here are some commonly requested questions relating to those two very important concepts:

1. What’s the principal big difference among wedge and ball bonding?

The relevant big difference lies in their bond formation mechanism; ball bonding uses a melted sphere when wedge employs direct stress with out pre-formations ensuing in one of a kind merits centered on software needs!

2. When must I opt one methodology over every other?

If you're looking at compact designs involving high-quality pitches—select ball bonds! However if working inside energy modules requiring longevity—wedge may possibly serve very best the following as an alternative!

three. Are there detailed elements most effective terrifi for one process?

Yes certainly! Gold works biggest with balls whilst aluminum/copper excel under wedges! Make certain you opt correctly depending upon your assignment requisites!

4. How does both strategy impact long-term reliability?

Generally communicating—a nicely-executed ball bond well-knownshows more desirable fatigue resistance! While wedges ship stunning moisture safeguard ensuring durability regardless!

five.Who grants guidance resources on these tactics?

Many universities offer guides along severa on line systems website hosting tutorials & webinars centred explicitly upon modifying abilities round these primary technology!!

Conclusion

Choosing between wedge vs ball bonding at last boils down personal desire dictated by unique challenge parameters—concerns along with drapery determination,can charge explanations,and preferred overall performance effects play pivotal roles influencing this resolution-making activity immensely!

Both tools have wonderful strengths; to that end understanding your software’s distinguished demands makes it possible for you leverage both technique nicely whilst maximizing productiveness yields for the duration of manufacturing cycles forward!