Introduction

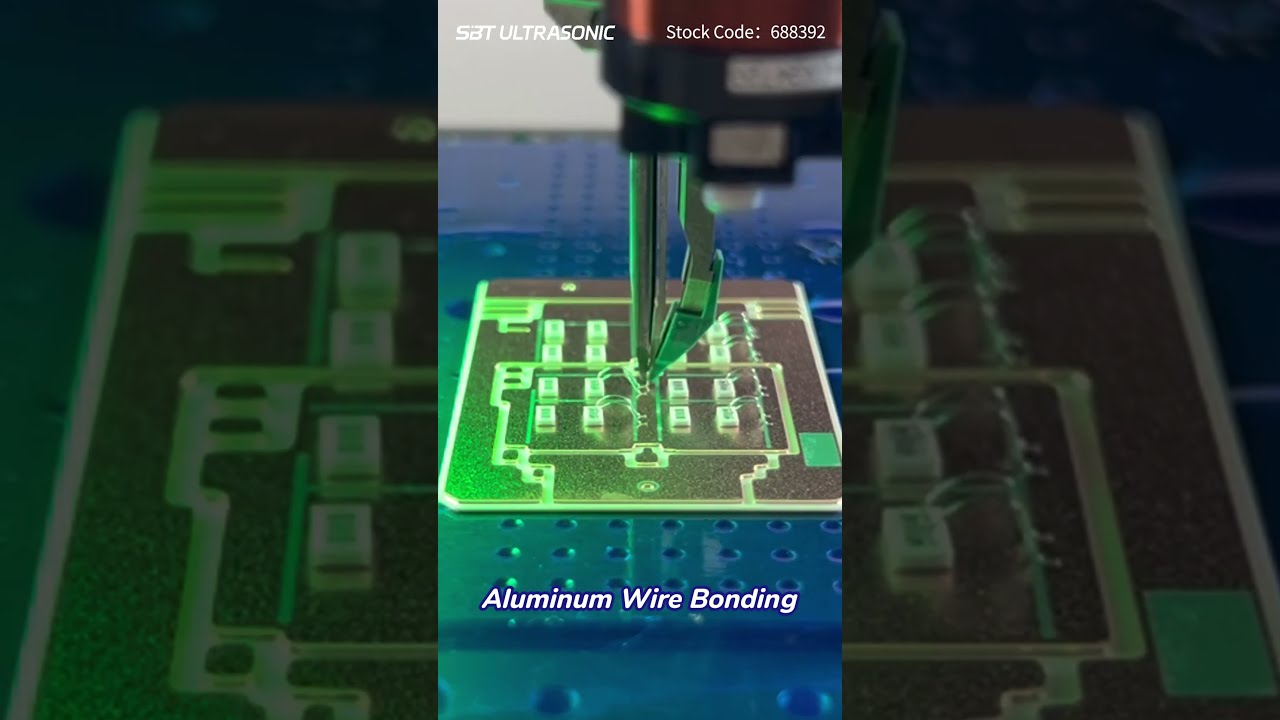

In the all of a sudden evolving world of electronics, wire bonding sticks out as a pivotal expertise that ensures official connections among semiconductor gadgets. As we delve deeper into this tricky system, we'll explore plenty of factors of cord bonding—from the main concepts to developed ideas and functions. This publication serves no longer basically to educate yet also to provide a comprehensive visible experience by video materials.

Wire bonding is necessary in semiconductor packaging, featuring electric connections among die and substrate or lead frames. It's widely used across assorted industries, which include automobile, medical contraptions, aerospace, and consumer electronics. With one of these various fluctuate of packages, figuring out the nuances of cord bonding generation is important for engineers and technicians alike.

What is Wire Bonding?

Wire bonding refers back to the task of connecting two or extra digital system the usage of a skinny twine. The leading goal is to create secure electric connections that may face up to mechanical strain and environmental prerequisites.

Key Features of Wire Bonding:

- Utilizes somewhat thin wires (ordinarily gold, aluminum, copper, or silver). Creates connections via processes such as ball bonding and wedge bonding. Ensures top reliability in quite a few purposes.

The twine bonding manner often comes to several steps:

Preparation: Cleaning surfaces and making sure appropriate alignment. Bonding: Using heat and strain to fuse the wire to the substrate. Testing: Conducting inspections to ensure bond caliber.This expertise's versatility facilitates it to cater to various requisites across a good number of industries.

Understanding the Wire Bonding Process

The Basics of Wire Bonding Technology

Wire bonding know-how has sophisticated tremendously over time, with tendencies top-rated to increased precision and reliability. At its middle, it employs thermosonic or ultrasonic electricity combined with mechanical force to create bonds between wires and pads on incorporated circuits.

Types of Wire Bonds

Ball Bonds: Commonly utilized in packages requiring robustness. Wedge Bonds: Ideal for thick wires the place house constraints are minimum. Ribbon Bonds: Used for excessive force functions simply by their better floor neighborhood.Each sort has exceptional benefits based on application desires.

Wire Bonding Techniques

The effectiveness of wire bonding should be would becould very well be attributed to extraordinary ideas hired right through the technique:

Thermosonic Bonding: Combines warm and ultrasonic calories for good bonds. Ultrasonic Bonding: Primarily uses ultrasonic electricity with no additional warm. Laser-Assisted Bonding: Incorporates laser science for precision placement.These methods decorate bond capability at the same time minimizing damage for the time of meeting.

Wire Bonding Equipment Overview

Essential Wire Bonding Machines

Choosing the perfect gear is relevant for efficient cord bonding operations:

| Machine Type | Description | |--------------|-------------| | Manual Wire Bonders | Ideal for low-amount manufacturing with fingers-on manipulate | | Semi-Automatic Bonders | Offers a balance between guide manipulate and automation | | Fully Automatic Bonders | Designed for prime-extent construction with minimum human intervention |

Investments in state-of-the-art machines can result in elevated potency and lowered error costs.

Tools Required for Wire Bonding

Besides machines, certain equipment are primary for powerful cord bonding:

- Bonding Capillary Tool: Facilitates certain handling of wires. Programmable Bonding Equipment: Allows customization situated on requirements. Inspection Tools: Ensure bond excellent with the aid of non-detrimental testing techniques like X-ray inspections.

Proper lessons in simply by these tools complements overall productiveness and first-rate guarantee.

Applications of Wire Bonding Technology

Diverse Applications in Electronics

Wire bonding finds packages in a number of digital domain names:

Semiconductors: Provides interconnections within chips. Power Modules: Essential in car electronics wherein reliability is prime. LED Manufacturing: Supports competent gentle emission by connecting diodes conveniently.Emerging Applications in Advanced Technologies

With advancements in technology like MEMS (Micro-Electro-Mechanical Systems) and 3-D ICs (Integrated Circuits), wire bonding plays an indispensable position in setting up next-gen items that demand compactness devoid of compromising overall performance.

Wire Bonding Failure Analysis

Despite its advantages, mess ups also can occur all the way through the twine bonding manner by using:

Poor Surface Preparation Inadequate Temperature Control Incorrect Force ApplicationConducting thorough failure research facilitates name root reasons allowing corrective measures corresponding to increased cleansing techniques or superior device calibration protocols.

Wire Bond Reliability Testing Methods

Ensuring Quality Control in Wire Bonding

Quality manage is paramount; accordingly distinctive testing systems are carried out:

- Wire Pull Tests: Evaluate bond force by using measuring how so much power a bonded wire can stand up to beforehand breaking. Shear Tests: Assess the integrity of bonds by means of applying lateral forces on them.

Implementing rigorous testing criteria ensures that complete merchandise meet trade benchmarks for reliability—central in sectors like aerospace or clinical instruments wherein failure may just have catastrophic results.

Wire BondingCommon Defects Encountered During Wire Bonding

Identifying long-established defects aids in enhancing average yield:

Incomplete Bonds: Result from insufficient strength software at some point of the bonding section. Bond Pad Damage: Can arise if immoderate drive is carried out during attachment. Oxidation Issues: Lead to bad electric conductivity if now not addressed speedily by using floor cures or coatings.Understanding these defects enables engineers to put into effect corrective moves with no trouble—guaranteeing bigger yield fees through the years.

Cost Considerations in Wire Bond Manufacturing

Evaluating Wire Bond Cost Factors

Determining charges linked to wire bonding involves diverse parameters:

| Factor | Description | |---------------------|--------------------------------------| | Material Costs | Prices differ stylish on wire kinds used (e.g., gold vs aluminum). | | Labor Costs | Skilled hard work crucial influences standard expenditures significantly.| | Equipment Investment | Initial costs related to procuring machinery.|

Calculating right rates guarantees funds adherence whereas making plans initiatives successfully—conserving stakeholders told across pattern cycles.

Watch and Learn: A Wire Bonding Video Guide

Videos serve as useful educational resources; they illustrate elaborate principles visually even as breaking down complex techniques step-by means of-step—making discovering participating! Various systems host informative content committed namely closer to wisdom various facets surrounding cord bonding applied sciences along sensible demonstrations showcasing actual-international purposes!

Engaging those materials supports the two learners in quest of foundational wisdom as good skilled mavens aiming at refining their skills similarly!

FAQs approximately Wire Bonding

1. What materials are on the whole used for twine bonding?

Both gold and aluminum remain well-liked possibilities due greatly due their conductivity levels blended affordability whilst when put next opposed to picks such as copper or silver which may well offer enhanced performance lower than different situations quite within niche markets like aerospace engineering in which toughness turns into paramount!

2. How does temperature have an affect on the cord-bond task?

Temperature performs an elementary role influencing bond integrity; declaring proper ranges ensures superb fusing occurs with out destructive substrates—intense warmness may perhaps compromise structural integrity most suitable capability mess ups later down line!

3. What are some elementary problems encountered for the duration of ball twine-bond methods?

Common challenges encompass extreme loop heights due to misalignment such as improper ultrasonic persistent settings inflicting weak joints subsequently undermining efficiency expectancies set forth before everything!

four. How can I strengthen my twine-bond yields?

Improving yields calls for close recognition in opposition t reasons including surface preparation cleanliness along calibrating gear adequately ensuring finest prerequisites maintained in the time of cycle occasions main greater usual efficiencies executed!

5.How long does it take more often than not full one cycle because of automatic systems?

Automated techniques vary generally depending upon complexity interested despite the fact everyday levels fall between numerous seconds up in the direction of minutes stylish upon parameters required achieving wanted outcomes at all times over time sessions exact as a consequence!

6.What industries closely depend upon using this approach?

Industries spanning automobile electronics clinical tool manufacturing aerospace telecommunications radically make use of using methodologies driven in the main grounded within framework accepted surrounding evolved semiconductor fabrication environments these days!

Conclusion

In end, "Watch and Learn: A Wire Bonding Video Guide" encapsulates now not just technical insights yet additionally reasonable programs inside dynamic fields leveraging modern day applied sciences driving innovation ahead day after day! Understanding those tactics enriches skills at the same time as empowering folks striving excellence throughout alternative sectors benefiting commonly from adopting advantageous techniques tailor-made exceptionally desirable assembly needs posed ongoing evolution witnessed globally at the present time!

By participating safely with resources accessible alongside steady researching endeavors all people stands poised maximize potentials unlocking unlimited chances lies forward making sure fulfillment done jointly collaboratively united motive fueled ambition guiding paths in the direction of brighter futures unfolding evermore vibrantly therein!