Introduction

In the ever-evolving panorama of electronics and semiconductor production, cord bonding has emerged as a imperative manner. This formula consists of making electric connections between semiconductor contraptions and their packaging by means of exceptional wires. Selecting the highest wires for semiconductor bonding packages is paramount to accomplishing reliability, efficiency, and price-effectiveness. With more than a few parts possible—gold, aluminum, copper, and silver—every with its interesting residences and applications—the choice on which twine to use can drastically influence the first-rate of the ultimate product.

This article explores every side of twine bonding in semiconductor programs, from knowledge the wire bonding task to interpreting alternative processes and applied sciences. We'll delve into the intricacies of cord fabrics preference, reliability aspects, user-friendly screw ups, and market concepts. Whether you are an engineer in quest of insights or a organization aiming to optimize your tactics, this complete e-book will serve as a useful useful resource.

What is Wire Bonding?

Wire bonding is a needed methodology used principally in semiconductor manufacturing to create electrical connections between incorporated circuits (ICs) and their respective substrates. The twine bonding system almost always employs skinny wires created from conductive constituents inclusive of gold or aluminum to set up these connections.

How Wire Bonding Works

The wire bonding means entails attaching one quit of a thin wire to a bond pad on the chip although securing the alternative cease to a lead body or substrate. The connection is formed by way of thermal vigour, stress, or ultrasonic vibrations that meld the metal surfaces at the same time. Understanding how cord bonding works lays the groundwork for deciding on the most efficient wires for distinct purposes.

Types of Wire Bonding Techniques

There are several forms of wire bonding ideas utilized in semiconductor production:

Ball Bonding: This contains growing a small ball at one cease of the twine prior to making contact with the chip's bond pad. Wedge Bonding: In this strategy, a wedge-formed instrument presses down onto equally surfaces without forming a ball. Ribbon Bonding: Utilizes flat ribbon wires rather than spherical ones for selected applications requiring better floor locations. Ultrasonic Bonding: Employs ultrasonic waves to strengthen bond force all the way through attachment.Each manner has its benefits and downsides; due to this fact, or not it's needed to come to a decision wisely depending on software requirements.

Wire Bonding Technology Overview

The advancements in twine bonding technological know-how have enabled manufacturers to improve yield rates, lower rates, and develop product performance in semiconductors.

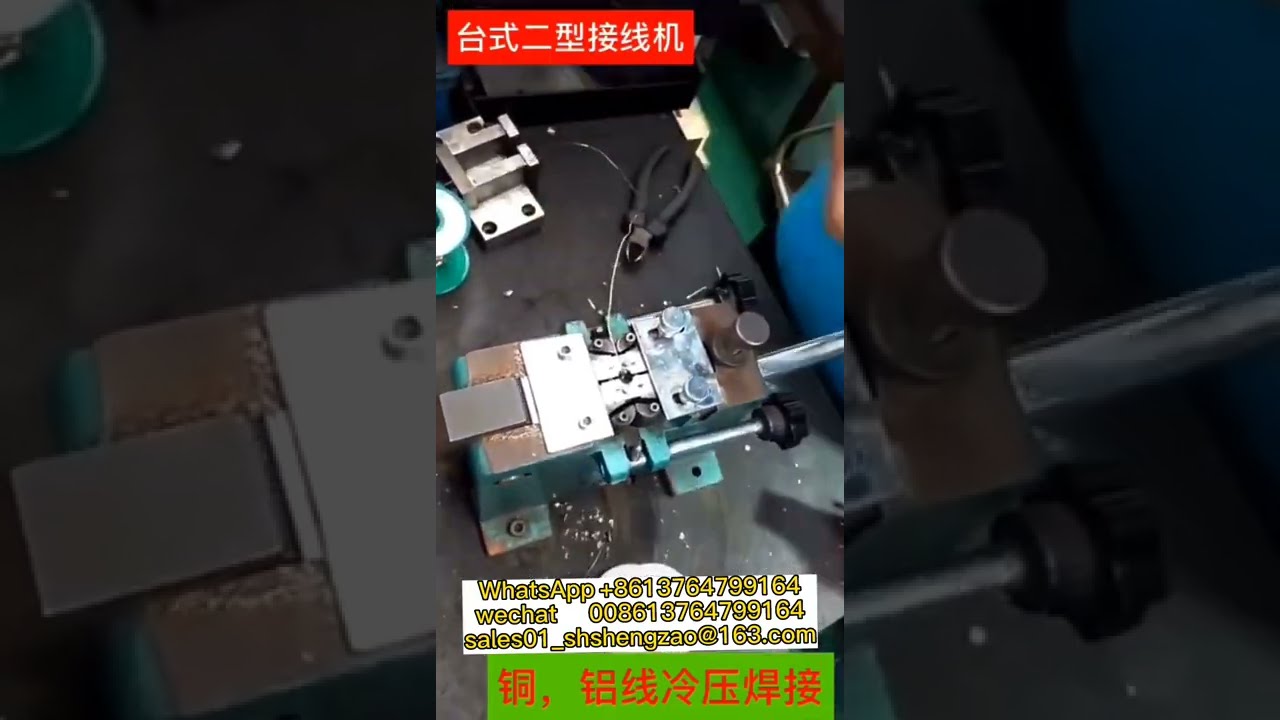

Wire Bonding Equipment

Wire bonding tools accommodates specialized machines designed for exceptional bonding programs which include ball bonders and wedge bonders. These machines can be manual or solely automatic relying on production wants. Factors which include velocity, precision, and straightforwardness of use should always be taken into consideration whilst opting for package on your facility.

Cost Considerations in Wire Bonding

When fascinated about twine bonding prices, one have got to account not simply for material charges but also system operation bills, exertions expenditures, and workable transform with the aid of screw ups. Evaluating these components guarantees that you just make informed judgements about your creation method.

Selecting Wires for Semiconductor Applications

Choosing suited wires plays a valuable position in making certain most appropriate functionality and durability of digital gadgets.

Gold vs Aluminum Wire Bonding

Gold wire bonding gives best suited conductivity however comes with greater drapery costs when put next to aluminum. On the alternative hand, aluminum is more can charge-high-quality but might not deliver equivalent stages of reliability in selected environments.

Table 1: Comparison Between Gold and Aluminum Wires

| Property | Gold Wire | Aluminum Wire | |-----------------------|----------------------|----------------------| | Cost | High | Low | | Conductivity | Excellent | Good | | Oxidation Resistance | High | Moderate | | Temperature Tolerance | High | Moderate |

Copper Wire Bonding Benefits

Copper wires are gaining status due to their leading conductivity in contrast to gold and aluminum at lower bills; having said that, they also latest demanding situations relating to oxidation.

Silver Wire Bonding Applications

Silver provides correct conductivity yet is usually likely to tarnishing through the years; therefore it’s aas a rule utilized in niche programs in which performance outweighs cost considerations.

Wire Bonding Quality Control Measures

Quality management is valuable in the time of all degrees of wire bonding operations—from textile range through to final inspection.

Wire Bond Inspection Methods

Various inspection programs are applied throughout the time of manufacturing:

- Visual Inspection X-ray Inspection Pull Testing Shear Testing

These methods assistance pick out defects early on even as making sure compliance with business criteria like JEDEC recommendations.

Common Wire Bond Failures and Analysis

Understanding overall failure modes can substantially make stronger reliability in creation:

Bond Pad Damage: Occurs resulting from extreme force throughout bonding. Incomplete Bonds: Result from insufficient vitality utilized for the duration of attachment. Oxidation Issues: Affect bond nice over time. Bond Lifting: Can arise if there’s insufficient adhesion among surfaces.Table 2: Common Failure Modes & Solutions

| Failure Mode | Description | Solution | |----------------------|----------------------------------|----------------------------------| | Bond Pad Damage | Physical hurt from tooling | Calibrate pressure settings | | Incomplete Bonds | Poor attachment | Adjust power settings | | Oxidation Issues | Surface degradation | Implement protective measures | | Bond Lifting | Insufficient adhesion | Optimize cleansing processes |

Wire Bond Process Control Techniques

Effective technique control leads in an instant closer to superior product good quality via minimizing variability across operations:

Calibration Procedures Environmental Controls (temperature/humidity) Regular Maintenance SchedulesImplementing these controls creates a solid production setting conducive for riskless outcome.

Applications of Wire Bonding in Semiconductors

Wire bonding reveals enormous software across assorted sectors inside of electronics:

Wire Bonding in Automotive Electronics

Automotive electronics count heavily on powerful wiring connections by means of harsh operating prerequisites like temperature fluctuations and mechanical vibrations—as a consequence necessitating tremendous bonds as a result of valuable concepts which includes thermosonic wedge bonding or exceptional pitch ball bonding processes adapted principally for car constituents.

Wire Bonding Innovations for Medical Devices

In medical machine production wherein precision concerns greatly—cutting edge systems as a result of micro-length bonded wires allow compact designs crucially helping sufferer security with no compromising function to that end enhancing both healing effectiveness whereas chopping total size constraints imposed before with the aid of old designs making use of primary approaches alone!

FAQ Section

1. What is twine bonding?

Wire bonding refers now not only wire bonding amtech generally refers lower back in direction of connecting chips inside digital assemblies yet additionally encompasses a variety of detailed methodologies hired depending upon wanted attributes admired such as flexibility with regards to geometrical constraints inherent throughout the time of varying industries starting from aerospace thru automobile markets alike!

2. How does gold compare with aluminum for cord bonding?

Gold presents greater conductivity along resistance opposed to corrosion whereas aluminum presents affordability coupled along ample efficiency — ultimately ultimate engineers desiring be aware industry-offs elegant upon given needs present themselves hence!

3. What are some trouble-free mess ups related to twine bonds?

Common disorders embrace incomplete bonds most advantageous toward compromised connections together with oxidization providing itself over lengthy publicity under negative stipulations necessitating steady inspections implemented typically ensuring sustained integrity across lifespan monitored heavily!

four.Can copper be used with ease inside of any precise context?

Indeed yes! Copper stands proud broadly speaking whilst dealing above all round high-functionality environments owing mostly attributed against extraordinary conductive homes exhibited most often yielding favorable outcome proven perpetually across dissimilar initiatives undertaken effectively!

5.What inspection methods are handy in the course of this total process?

Several methodologies exist adding visual exams played manually against automated recommendations employing x-rays permitting thorough verification with no compromising effectivity thereby asserting normally top output criteria accomplished seamlessly!

6.Where might I in finding further components around this subject?

A breadth exists encompassing housing exact tutorials hosted online overlaying the entirety referring to principal rules along complicated ideas employed thoroughly yielding potent consequences performed continually across distinctive tasks undertaken diligently striving against excellence without end pursued inside engineering nation-states these days!

Conclusion

Selecting the Best Wires for Semiconductor Bonding Applications isn’t with reference to picking a fabric; it’s approximately awareness how that alternative influences each part of production—from reliability issues properly by way of payment implications—and how it aligns with market traits moving forward into long run generations inside era-pushed industries quickly evolving daily! By grasping those materials wholly even as exploring modern options presented often at the moment we empower ourselves towards achieving excellence perennially admired tirelessly inside of each subject enterprise pursued!