Introduction

In the briskly evolving landscape of electronics production, the significance of safe interconnections are not able to be overstated. One such methodology that has won traction in fresh years is insulated twine bonding. This article delves into the complex world of twine bonding, exploring its tactics, technology, approaches, and packages whilst emphasizing how insulated twine bonding complements performance and longevity.

What is Insulated Wire Bonding?

Insulated wire bonding entails using insulation supplies on bonding wires wire bonding process to enhance electrical functionality while minimizing risks along with quick circuits and pass-speak. This technique is pretty a good option in top-density packaging programs in which space is at a top rate. By imparting one more layer of insurance plan, insulated wire bonding ensures that electronic contraptions are usually not purely powerful however also lengthy-lasting.

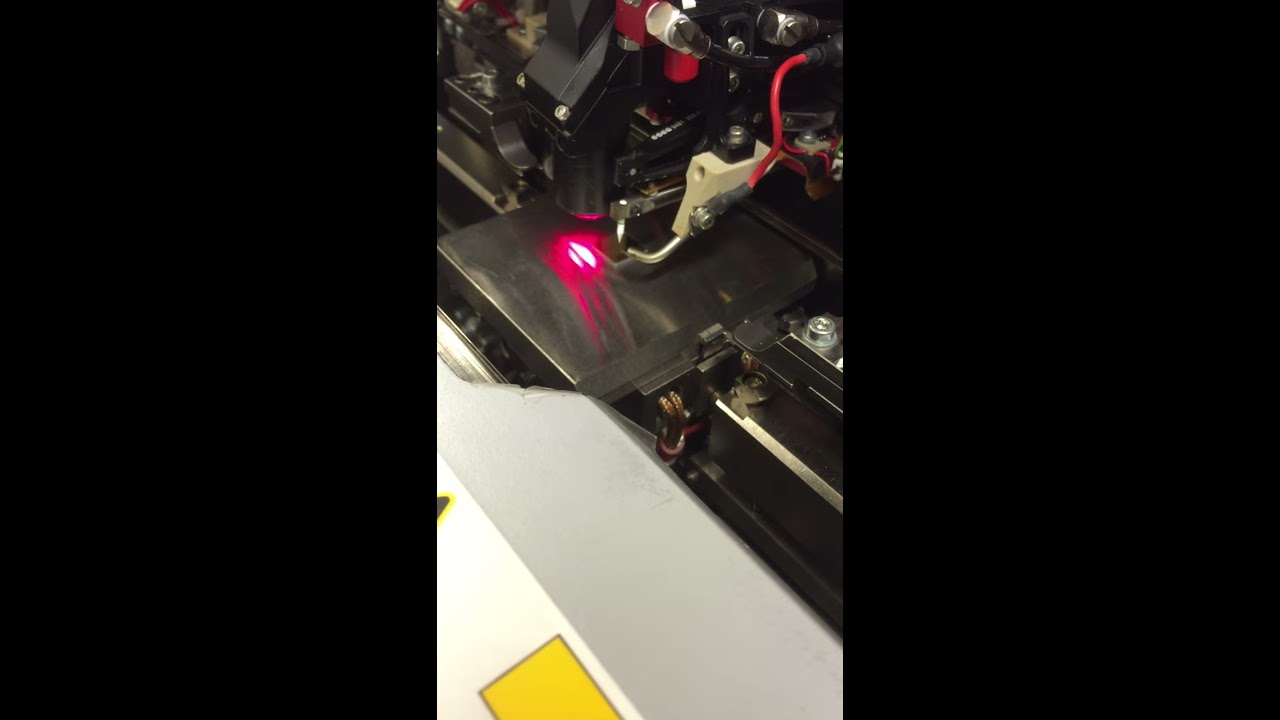

Understanding the Wire Bonding Process

The twine bonding process consists of quite a few very important steps:

Preparation: The substrate is prepared by using cleaning and employing a conductive layer. Wire Selection: The marvelous style of cord (gold, aluminum, copper) is selected elegant on application specifications. Bonding: A bond is created among the cord and the substrate driving heat, force, or ultrasonic power. Testing: The bonds are proven for reliability because of diverse programs like pull exams or shear checks.Types of Insulation Materials Used

The collection of insulation cloth performs a pivotal role in making a choice on the effectiveness of insulated twine bonding. Common resources include polyimide films, silicone rubbers, and epoxy resins. Each drapery offers targeted homes equivalent to thermal balance and chemical resistance.

The Importance of Wire Bonding Technology

Advancements in Wire Bonding Equipment

The evolution of cord bonding technology has resulted in the progression of advanced machines in a position to executing tricky techniques successfully. Modern cord bonding machines integrate automation beneficial properties that optimize creation cycles whereas conserving prime precision.

Benefits of Automated Wire Bonding Machines

Automated machines reinforce either velocity and consistency in production environments. With capabilities like programmable settings and factual-time tracking procedures, manufacturers can obtain higher yields with decreased error rates.

Wire Bonding Techniques Explained

Ball Bonding vs Wedge Bonding

Two imperative innovations dominate the wire bonding landscape:

- Ball Bonding: Utilizes a small ball shaped at the end of a gold or aluminum wire to create a bond. Wedge Bonding: Employs a wedge-fashioned instrument to make connections; most effective for thicker wires or where area constraints exist.

Both processes have their blessings relying on software specifics.

Thermosonic vs Ultrasonic Bonding

These suggestions involve the different vigour resources:

- Thermosonic Bonding combines warmness with ultrasonic strength for potent bonds. Ultrasonic Bonding depends completely on ultrasonic vibrations; that's turbo but might not present as stable a connection as thermosonic approaches.

Wire Bonding Applications Across Industries

Wire Bonding in Semiconductors

In semiconductor production, twine bonding establishes essential connections between chips and substrates. Its reliability at once affects instrument performance.

Applications in Automotive Electronics

As automobiles emerge as greater reliant on electronics for operation and safeguard capabilities, beneficial cord bonding strategies are principal to verify reliability below harsh stipulations.

Medical Devices and Wire Bonding Solutions

Insulated cord bonding reveals its way into medical contraptions the place reliability can mean lifestyles or loss of life. Whether securing sensors or connecting formula within implants, it’s a must have that those bonds withstand rigorous checking out.

Wire Bond Quality Control Measures

Ensuring top quality bonds requires strict excellent regulate measures all around the manufacturing course of.

Common Testing Methods for Wire Bonds

Pull Test Shear Test X-ray Inspection Visual InspectionThese assessments guide title skills topics early in construction cycles formerly they strengthen into costly disasters.

Wire Bond Reliability Factors

Environmental Considerations in Wire Bond Reliability

Environmental components together with temperature fluctuations and moisture stages notably have effects on bond integrity over the years.

- Implement ESD policy cover innovations. Use conformal coatings for more suitable sturdiness against environmental stressors.

Long-term Reliability Testing Procedures

Conduct conventional lengthy-term reliability checks to be certain that that bonds can face up to operational calls for over prolonged classes.

Challenges Faced in Insulated Wire Bonding

Despite its benefits, insulated twine bonding comes with demanding situations:

Selecting magnificent insulation supplies will be problematical. Machine calibration should be specific to circumvent defects all over manufacturing. Environmental regulations can even prohibit yes materials utilized in insulating layers.Wire Bond Failure Analysis Techniques

Understanding why bonds fail is quintessential for improving strategies:

Analyze root reasons using failure research protocols. Implement corrective actions depending on findings from failure mode prognosis studies. Regularly review overall performance documents to identify developments most effective to mess ups.Costs Associated with Wire Bond Processes

Understanding charges involving cord bonding is helping enterprises allocate budgets extra readily:

| Type | Cost Estimate | |-----------------------------|---------------| | Manual Wire Bonder | $5K - $20K | | Semi-Automatic Bonder | $20K - $75K | | Fully Automatic Bonder | $100K+ |

Investments range notably founded on device advantage and automation phases.

Training Programs for Effective Wire Bonding

To save velocity with market developments:

- Implement ongoing exercise classes masking matters from classic ideas to complicated ways. Encourage participation in on-line programs or webinars concentrated on state-of-the-art tendencies in insulated wire bonding expertise.

Learning Resources for Engineers

For engineers trying to master insulated wire bonding:

- Access educational sources inclusive of "twine bonding educational" videos on-line. Download "twine bonding PDF" files from reliable assets detailing systems and methodologies.

Case Studies Illustrating Successful Applications

Examining effective case reviews highlights how insulated cord bonding enhances overall performance across a number of sectors:

Power module packages integrating ribbon bonded technology greatest to stronger efficiency quotes by 30%. Medical units utilising aluminum bonded wires showcasing long-time period durability even less than tension trying out situations.Frequently Asked Questions (FAQs)

1. What are the most different types of insulated wires used in electronics?

Insulated wires normally comprise aluminum wires covered with layers like polyimide or silicone rubber that expand durability and overall performance less than quite a lot of situations.

2. How does temperature affect the effectiveness of insulated cord bonds?

Temperature variations can cause expansion or contraction which can weaken bond integrity; for that reason making certain perfect thermal management throughout operation is significant.

3. What trying out tips be sure nice control in bonded wires?

Quality management employs a variety of checking out programs including pull tests, shear assessments in conjunction with visual inspection systems ensuring each one bond meets required requirements previous deployment into remaining merchandise.

four. Can you provide an explanation for how environmental motives effect bonded wires?

Moisture publicity would lead corrosion although severe temperatures might set off fatigue; consequently utilizing protective coatings becomes mandatory when designing assemblies subjected harsher environments!

5 What industries merit such a lot from advanced insulating procedures?

Industries consisting of automotive electronics healthcare techniques aerospace all leverage more desirable insulation homes making sure nontoxic functioning over longer lifespans!

6 Are there unique workout techniques plausible focusing totally upon gaining knowledge of those thoughts?

Yes! There are specialized courses built concentrated on participants aiming get hold of accomplished skillsets surrounding leading-edge procedures applied within this subject!

Conclusion

In conclusion, insulated cord bonding represents an crucial advancement inside of digital production strategies at the present time! As we explored for the period of this accomplished consultant—it no longer in basic terms improves overall efficiency however also extensively enhances longevity across multiple packages ranging car sectors scientific units vigour modules alike! By leveraging emerging technologies coupled along universal practices engineers will continue pushing barriers growing ingenious solutions elevating principles high-quality reliability!