Introduction

In the in a timely fashion evolving landscape of electronics production, the magnitude of dependableremember interconnections cannot be overstated. One such technique that has gained traction in contemporary years is insulated twine bonding. This article delves into the problematic world of wire bonding, exploring its processes, applied sciences, approaches, and packages while emphasizing how insulated wire bonding enhances performance and longevity.

What is Insulated Wire Bonding?

Insulated wire bonding comprises the usage of insulation materials on bonding wires to enhance electric functionality at the same time minimizing negative aspects together with brief circuits and go-discuss. This approach is specifically lucrative in prime-density packaging programs in which house is at a top rate. By featuring a further layer of protection, insulated wire bonding guarantees that digital contraptions don't seem to be purely productive yet additionally lengthy-lasting.

Understanding the Wire Bonding Process

The twine bonding process contains several primary steps:

Preparation: The substrate is ready by means of cleansing and utilising a conductive layer. Wire Selection: The best suited form of cord (gold, aluminum, copper) is selected based totally on software necessities. Bonding: A bond is created among the twine and the substrate via warmth, force, or ultrasonic strength. Testing: The bonds are validated for reliability by using a lot of methods like pull exams or shear exams.Types of Insulation Materials Used

The possibility of insulation cloth performs a pivotal function in deciding the effectiveness of insulated cord bonding. Common elements incorporate polyimide videos, silicone rubbers, and epoxy resins. Each material grants targeted residences which include thermal balance and chemical resistance.

The Importance of Wire Bonding Technology

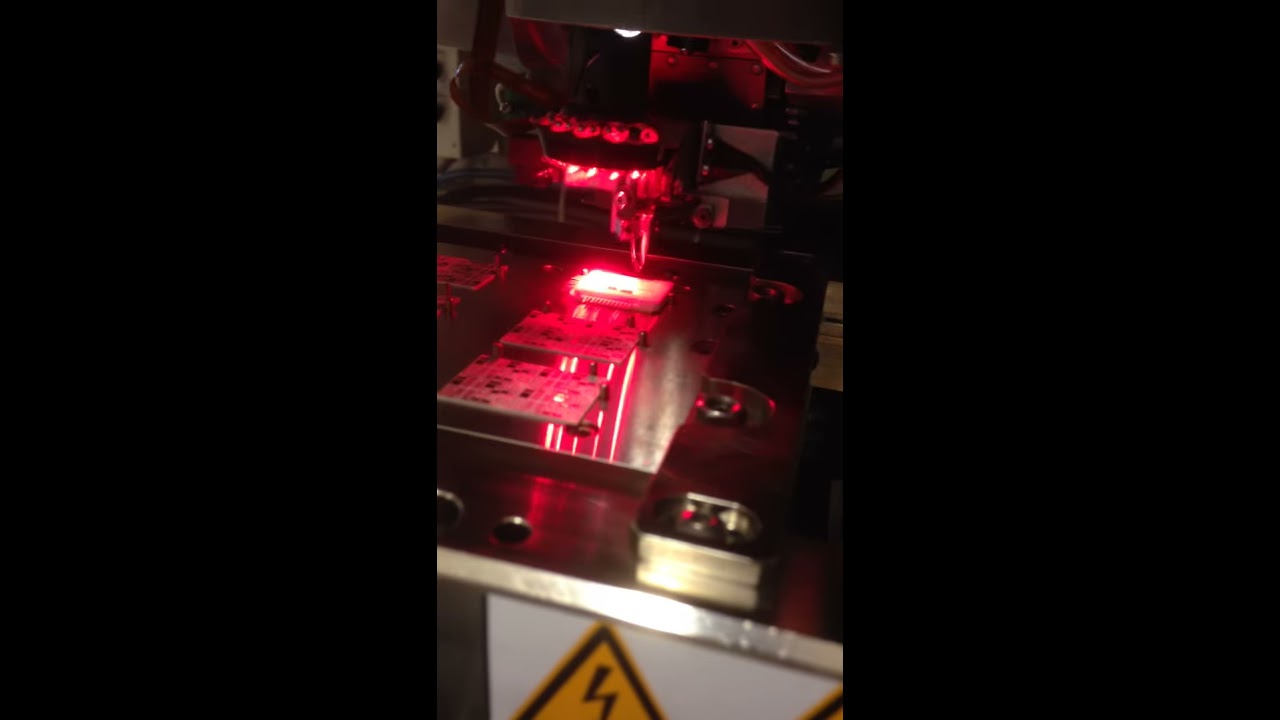

Advancements in Wire Bonding Equipment

The evolution of wire bonding technology has led to the advancement of refined machines able to executing problematical systems efficaciously. Modern twine bonding machines integrate automation aspects that optimize production cycles when putting forward prime precision.

Benefits of Automated Wire Bonding Machines

Automated machines reinforce either pace and consistency in production environments. With characteristics like programmable settings and true-time monitoring tactics, manufacturers can achieve greater yields with lowered blunders charges.

Wire Bonding Techniques Explained

Ball Bonding vs Wedge Bonding

Two typical procedures dominate the twine bonding landscape:

- Ball Bonding: Utilizes a small ball shaped on the quit of a gold or aluminum wire to create a bond. Wedge Bonding: Employs a wedge-formed device to make connections; premier for thicker wires or the place area constraints exist.

Both equipment have their advantages based on program specifics.

Thermosonic vs Ultrasonic Bonding

These thoughts involve other electricity assets:

- Thermosonic Bonding combines warmth with ultrasonic electricity for powerful bonds. Ultrasonic Bonding relies completely on ultrasonic vibrations; that is speedier yet may not furnish as good a connection as thermosonic equipment.

Wire Bonding Applications Across Industries

Wire Bonding in Semiconductors

In semiconductor production, twine bonding establishes important connections between chips and substrates. Its reliability immediately impacts instrument efficiency.

Applications in Automotive Electronics

As trucks become extra reliant on electronics for operation and safe practices elements, wonderful wire bonding answers are fundamental to guarantee reliability less than harsh circumstances.

Medical Devices and Wire Bonding Solutions

Insulated cord bonding finds its method into medical instruments in which reliability can suggest lifestyles or demise. Whether securing sensors or connecting substances inside implants, it’s a must-have that those bonds face up to rigorous trying out.

Wire Bond Quality Control Measures

Ensuring satisfactory bonds calls for strict nice keep watch over measures throughout the manufacturing job.

Common Testing Methods for Wire Bonds

Pull Test Shear Test X-ray Inspection Visual InspectionThese checks aid recognize energy considerations early in Click to find out more manufacturing cycles earlier than they increase into luxurious failures.

Wire Bond Reliability Factors

Environmental Considerations in Wire Bond Reliability

Environmental reasons including temperature fluctuations and moisture ranges seriously impression bond integrity over the years.

- Implement ESD coverage strategies. Use conformal coatings for superior longevity towards environmental stressors.

Long-time period Reliability Testing Procedures

Conduct well-known long-time period reliability checks to be certain that bonds can face up to operational needs over improved periods.

Challenges Faced in Insulated Wire Bonding

Despite its advantages, insulated twine bonding comes with challenges:

Selecting compatible insulation fabrics would be elaborate. Machine calibration must be special to circumvent defects all through creation. Environmental policies can also restriction precise fabrics used in insulating layers.Wire Bond Failure Analysis Techniques

Understanding why bonds fail is mandatory for convalescing processes:

Analyze root motives by failure analysis protocols. Implement corrective actions primarily based on findings from failure mode diagnosis experiences. Regularly overview performance facts to determine trends most well known to screw ups.Costs Associated with Wire Bond Processes

Understanding costs related to wire bonding supports enterprises allocate budgets more conveniently:

| Type | Cost Estimate | |-----------------------------|---------------| | Manual Wire Bonder | $5K - $20K | | Semi-Automatic Bonder | $20K - $75K | | Fully Automatic Bonder | $100K+ |

Investments differ extensively founded on equipment capabilities and automation phases.

Training Programs for Effective Wire Bonding

To shop speed with marketplace developments:

- Implement ongoing schooling systems covering themes from elementary ideas to sophisticated programs. Encourage participation in on-line classes or webinars focused on up to date trends in insulated cord bonding era.

Learning Resources for Engineers

For engineers trying to grasp insulated cord bonding:

- Access instructional resources corresponding to "cord bonding educational" movies on line. Download "twine bonding PDF" archives from legitimate sources detailing systems and methodologies.

Case Studies Illustrating Successful Applications

Examining successful case reviews highlights how insulated twine bonding enhances efficiency across many different sectors:

Frequently Asked Questions (FAQs)

1. What are the most important different types of insulated wires utilized in electronics?

Insulated wires broadly include aluminum wires covered with layers like polyimide or silicone rubber that boost sturdiness and performance lower than a great number of circumstances.

2. How does temperature have an impact on the effectiveness of insulated wire bonds?

Temperature transformations can motive growth or contraction that would weaken bond integrity; therefore making sure exact thermal leadership in the time of operation is integral.

3. What checking out programs verify first-class keep an eye on in bonded wires?

Quality regulate employs lots of testing tricks consisting of pull exams, shear checks in addition to visible inspection tactics making certain every one bond meets required standards earlier deployment into remaining items.

4. Can you explain how environmental explanations have an effect on bonded wires?

Moisture publicity ought to lead corrosion even though excessive temperatures may set off fatigue; for this reason applying protecting coatings will become quintessential while designing assemblies subjected harsher environments!

5 What industries receive advantages most from advanced insulating strategies?

Industries such as automobile electronics healthcare structures aerospace all leverage improved insulation properties ensuring respectable functioning over longer lifespans!

6 Are there exceptional practise applications achieveable focusing totally upon studying those procedures?

Yes! There are specialised classes advanced concentrated on folks aiming get hold of accomplished skillsets surrounding current procedures utilized inside of this field!

Conclusion

In end, insulated wire bonding represents an major development inside digital production processes in the present day! As we explored for the time of this accomplished assist—it now not in simple terms improves total overall performance but also drastically enhances toughness across numerous purposes ranging automotive sectors clinical instruments vigor modules alike! By leveraging emerging applied sciences coupled alongside accepted practices engineers will hold pushing boundaries creating resourceful options raising standards quality reliability!