Introduction

In the arena of electronics, the cord bonding course of stands as a quintessential methodology for commencing electric connections among semiconductor devices. Whether it’s for incorporated circuits (ICs), microcontrollers, or stepped forward vigor modules, wire bonding generation plays a indispensable role in ensuring reliability and efficiency. As electronics maintain to shrink in dimension while expanding in complexity, techniques in skinny and thick cord bonding methods have gotten increasingly vital.

Wire bonding techniques might possibly be largely categorized into a few styles, inclusive of ball bonding, wedge bonding, ribbon bonding, and their variations. Each formulation has its selected functions and blessings depending on elements just like the supplies used, environmental stipulations, and machine performance. In this article, we delve into the cutting edge improvements in the two skinny and thick twine bonding ways which might be shaping the destiny of semiconductor manufacturing.

What is Wire Bonding?

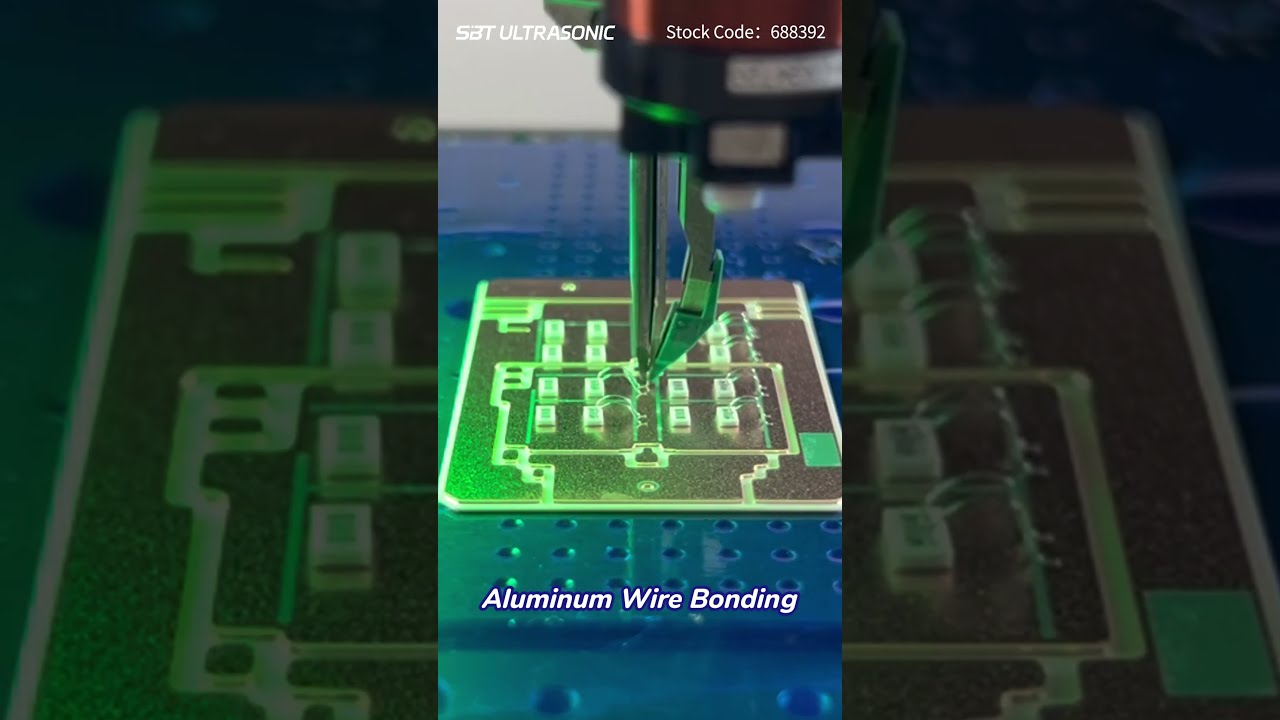

The wire bonding process is a strategy used to attach two electronic add-ons via superb wires made of materials like gold, aluminum, copper, or silver. This method is predominant for developing the interconnections crucial for units to serve as safely.

How Wire Bonding Works

At its middle, twine bonding includes numerous steps:

Preparation: The floor of the semiconductor chip needs to be cleaned and willing for bonding. Placement: A small twine is hooked up to the bond pad at the chip by using either warm or ultrasonic vitality. Formation: The cord is then looped to achieve any other bond pad or substrate where it'll be connected. Bond Creation: The final step includes utilising tension and heat (or sonic vigor) to create a powerful mechanical and electrical connection.Types of Wire Bonding

Understanding quite a lot of types of wire bonding is helping brands go with the accurate process for his or her different applications:

- Ball Bonding: Utilizes a small ball formed on the conclusion of a cord that bonds to the chip’s pad. Wedge Bonding: Employs a wedge-shaped software that compresses against each surfaces. Ribbon Bonding: Involves wider ribbons of steel used ordinarily in high-vitality applications.

Innovations in Thin Wire Bonding Techniques

Advantages of Thin Wire Bonding

Thin twine bonding can provide a number of blessings:

Space Efficiency: Reduced length permits more aspects on a single chip. Improved Performance: Lower inductance paths result in enhanced sign integrity. Cost-Effectiveness: Less subject material usage interprets into cut bills.Materials Used in Thin Wire Bonding

Thin wires are steadily comprised of:

- Gold: Known for its mind-blowing conductivity however will be dear. Aluminum: A payment-high-quality alternative with first rate conductivity. Copper: Offers top conductivity however requires cautious coping with through oxidation trouble.

Emerging Technologies in Thin Wire Bonding

Recent developments contain:

- Increased automation within skinny twine bonding machines for precision. Enhanced management techniques that enable for genuine-time changes all the way through the bonding strategy.

Table 1: Comparison of Thin Wire Materials

| Material | Conductivity | Cost | Applications | |-------------|--------------|-------------|------------------------| | Gold | Excellent | High | High-performance ICs | | Aluminum | Good | Medium | General electronics | | Copper | Very Good | Low | Budget-sensitive designs |

Innovations in Thick Wire Bonding Techniques

Overview of Thick Wire Bonding Process

Thick twine bonding regularly uses large diameter wires (sometimes more suitable than 0.8 mm) perfect for excessive-contemporary programs resembling energy amplifiers or strength modules.

Benefits of Using Thick Wires

Higher Current Capacity: Ideal for strength electronics requiring widespread existing pass. Robustness: Thicker wires present mechanical balance towards vibration and thermal stresses.New Developments in Thick Wire Binding Technologies

Recent techniques encompass:

- Advanced thermal administration methods included into thick cord bonds that enhance reliability beneath rigidity stipulations. Enhanced testing methodologies aimed toward improving nice manage at some stage in construction methods.

Wire Bonding Machine Technologies

Types of Wire Bonding Machines

Selecting the ideal computing device is integral based to your utility necessities:

Manual Machines: Suitable for low-quantity production but require trained operators. Semi-Automatic Machines: Offer more desirable efficiency whilst nevertheless wanting a few human intervention. Fully Automatic Machines: Ideal for top-quantity production with regular satisfactory output.Features to Consider When Choosing a Machine

When choosing a wire bonding machine, don't forget components like speed, accuracy, ease of use, and protection requirements.

Table 2: Comparison of Machine Types

| Type | Speed | Accuracy | Maintenance | |--------------------|---------|------------|--------------| | Manual | Low | Moderate | High | | Semi-Automatic | Medium | High | Medium | | Fully Automatic | Very High| Very High | Low |

Wire Bonding Applications Across Industries

Wire bonding know-how finds tremendous program across a variety of sectors:

1. Electronics Industry

Used predominantly in IC packaging and circuit board assembly.

2. Automotive Electronics

Critical for making sure solid connections within car manage gadgets.

three. Aerospace Applications

Employed in radar platforms and satellite tv for pc communications the place reliability is paramount.

four. Medical Devices

Essential for scientific machine the place overall performance can influence affected person safety straight.

Wire Bonding Failure Analysis

Understanding strength failure modes is a very powerful to improve reliability effects:

Common Failure Modes

Some user-friendly complications embody:

Bond Lifting: Often due to bad surface practise or excessive warmness during bonding. Heel Crack: Can turn up through mechanical stresses submit-bond formation. Oxidation: Leads to terrible electrical performance if now not controlled excellent.Frequently Asked Questions (FAQs)

li26/ol6/li27li27/ol7li28# How does temperature have an effect on the wire bonding technique?- Temperature plays a important position; too high would possibly motive degradation although too low can bring about incomplete bonds.

- Automated machines offer consistency and pace which might be valuable for wide-scale construction runs.

- Your selection ought to rely on explanations together with area constraints, required present capacity, and design requisites.

Conclusion

The techniques in skinny and thick cord bonding programs continue to pressure improvements throughout dissimilar industries—from buyer electronics to aerospace packages—guaranteeing robust connections that keep up brand new electronic gadgets' increasing calls for for pace and potency. By figuring out those tricks' intricacies—which include their respective advantages, challenges, knowledge failure modes—and leveraging cutting-edge equipment tailored particularly in the direction of these strategies—engineers can determine they harness greatest performance even as minimizing prices associated with screw ups or defects.

In this exploration of "Innovations in Thin and Thick Wire Bonding Techniques," we've exposed how imperative those processes are inside modern-day fast-paced technological panorama even as highlighting key facets inclusive of materials option nuances with the aid of actual-global examples—all supposed closer to Have a peek here empowering engineers with awareness obligatory no longer very nearly what exists this day yet additionally what is seemingly day after today!