Introduction

In the ever-evolving panorama of semiconductor manufacturing, precision and performance are paramount. One important component that ordinarily goes neglected is the dimensions of ribbon bonding wire used in the wire bonding course of. Proper option of twine bonding size can enormously effect reliability, overall performance, and common production quotes. This article delves into the intricacies of determining the most useful ribbon bonding twine size, exploring different factors worried inside the wire bonding manner, applied sciences possible, and most reliable practices for reaching successful outcomes.

Understanding Ribbon Bonding Wire Size

When it involves wire bonding technological know-how, identifying the proper ribbon bonding twine dimension isn't really only a remember of desire; that's a technology. A myriad of things impacts this determination:

What Is Ribbon Bonding?

Ribbon bonding is a popular technique in semiconductor packaging in which skinny steel ribbons are used to attach included circuits (ICs) to substrates or other ICs. It makes use of a really expert ribbon bonding computer capable of growing solid connections at the same time declaring low thermal resistance.

Why is Wire Size Important?

The measurement of the ribbon bonding cord influences various parameters:

- Bond Strength: Thicker wires typically furnish more advantageous bonds because of the multiplied contact location. Thermal Conductivity: Larger wires can also increase warm dissipation in continual applications. Electrical Performance: The size affects resistance degrees; greater diameters scale back resistance yet should be bulky in tightly packed layouts.

Determining Factors for Ribbon Bonding Wire Size

1. Application Requirements

Different applications have special calls for which can dictate twine dimension. For illustration, top-frequency purposes may perhaps profit from thinner wires to lessen inductance.

2. Type of Materials Used

The drapery performs a sizable function; gold, aluminum, copper, and silver all have distinctive mechanical properties impacting the option of thickness and width.

three. Environmental Conditions

Conditions inclusive of temperature permutations or humidity can have an impact on bond reliability. Selecting an acceptable ribbon calls for consideration of those environmental factors.

4. Manufacturing Process Limitations

Compatibility with latest manufacturing methods and device is indispensable. The specific cord have got to fit throughout the competencies of purchasable machines.

Wire Bonding Techniques Involved

Types of Wire Bonding Processes

There are numerous recommendations applied inside the industry:

Ball Wire Bonding

This approach involves forming a ball at the give up of a twine through heating previously making bonds on pads.

Wedge Wire Bonding

Utilizing a wedge-shaped instrument, this means creates bonds by compressing skinny wires onto pads with out forming a ball.

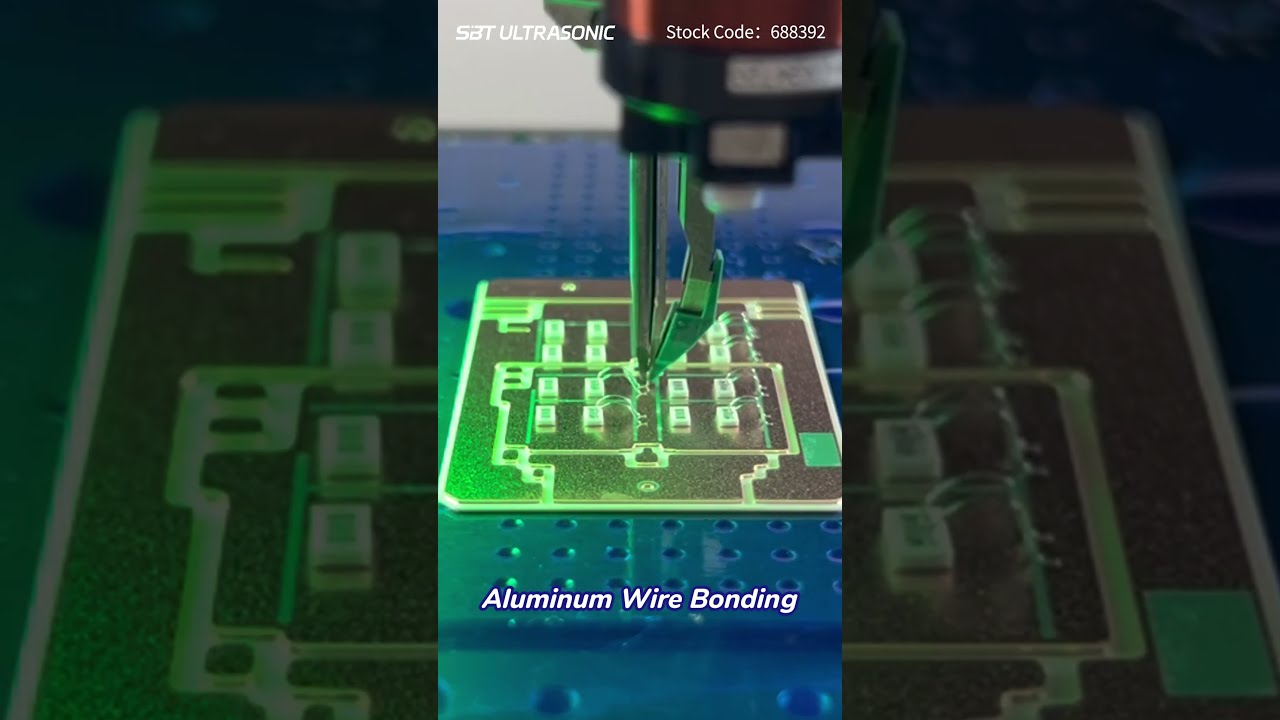

Ribbon Wire Bonding

A newer components that employs flat ribbons as opposed to round wires—most suitable for top-force programs on account of their awesome thermal features.

Evaluating Ribbon Bonding Equipment

Choosing splendid methods is obligatory for victorious ribbon bonding:

1. Manual vs Automatic Machines

Manual machines offer flexibility however require expert operators while absolutely automatic machines enhance throughput but would restriction adaptability.

2. Programmable Bonding Machines

These allow precise management over parameters like velocity and pressure carried out for the time of the bonding process, predominant for achieving repeatable great ideas.

Applications of Ribbon Bonding

Ribbon bonding has different packages throughout industries:

1. Power Modules

These require sturdy connections because of the excessive currents and thermal stresses; hence choicest ribbon sizes are crucial for reliability.

2. Consumer Electronics

In instruments like smartphones and laptops, the place space is restrained yet efficiency stays paramount, deciding on smaller ribbon sizes may just beef up usability without sacrificing high quality.

Challenges in Ribbon Bonding

While ribbon bonding supplies a great deal of benefits, demanding situations remain:

1. Wire Bonding Failure Analysis

Understanding failure modes is central for recuperating bond exceptional and durability as a result of rigorous testing protocols which include pull tests and shear assessments.

Key Factors Leading to Failures:

- Improper bond pad designs Inadequate environmental controls Lack of exact education among operators

Wire Bonding Reliability Considerations

Reliability in cord bonding hinges on multiple elements:

- Consistency in bond strength Resistance to environmental degradation Overall toughness beneath operational stresses

Cost Implications Of Ribbon Bonding Sizes

Cost is often an overriding component influencing judgements on cord sizes:

1. Material Costs vs Performance Gains

While thicker ribbons may also incur greater drapery expenditures upfront, they could lead to decreased disasters and lessen warranty claims down the line.

2. Production Efficiency Impact

Choosing an irrelevant size may perhaps Learn more necessitate further cycle instances or rework—motives that would increase manufacturing bills considerably through the years.

Quality Control Measures In Ribbon Bonding

Ensuring caliber for the period of the manufacturing task includes meticulous inspection protocols employing non-negative testing equipment reminiscent of X-ray inspections or automated bond inspections to ascertain joint integrity pre-and put up-construction degrees.

Conclusion on Determining Optimal Ribbon Bonding Wire Size

Finding the suitable balance with regards to selecting an most beneficial ribbon bonding cord size encompasses understanding program demands, comparing kit functions, navigating settlement implications even as making certain adherence to nice standards right through manufacturing cycles.

FAQs

Q1: What ingredients are mostly used for ribbon bonding wires?

A: Common resources encompass gold for its superb conductivity and aluminum through its settlement-effectiveness and weight blessings.

Q2: How does environmental situation have an affect on ribbon bonding?

A: Environmental motives like humidity or temperature fluctuations can impact bond potential; suited controls would have to be widespread throughout construction techniques.

Q3: Are there exceptional checking out techniques for assessing bond quality?

A: Yes! Methods which includes pull assessments and shear checks are broadly utilized alongside X-ray inspections for non-destructive tests.

Q4: Can I use automated machines for small-scale productions?

A: While solely computerized machines spice up throughput correctly acceptable towards high volumes; semi-vehicle innovations can also be hired conveniently based upon venture necessities.

Final Thoughts

In precis, finding out optimum ribbon bonding cord dimension includes cautious consideration throughout diversified dimensions—from application standards through check opinions up until eventually thorough high-quality regulate measures earlier in addition to ongoing technological developments shaping destiny methodologies inside this section normally evolving industry panorama!